| Alkali-silica reactivity (ASR), a pervasive durability problem that

occurs in portland cement concrete, is responsible for the premature

deterioration of various types of concrete structures in the United States

and around the world. While lithium compounds have been recognized for more

than 50 years as being effective in preventing concrete expansion due to

ASR, there has been increased interest in recent years in using them to both

treat existing structures and as a preventive measure in new concrete

construction. |

| The best way to avoid ASR in new concrete is to take

precautions in the mix design. These include testing aggregates for

reactivity; use of low-alkali cements, suitable pozzolans like ASTM C-618

Class F fly ash, and lithium-based admixtures. |

How lithium inhibits ASR?

Lithium nitrate reaction with reactive silica

and moisture is similar to other alkalies such as sodium and

potassium. Unlike ASR, however, the gel formed by Lithium Nitrate with alkalis

does not absorb excess moisture, preventing harmful expansion. |

| From the industry's point-of-view, use of an ASR

inhibitor not only better serves clients, but also can protect from

potential legal action that could arise if ASR is not mitigated when

state-of-the-art remedies are available. |

|

The cracks radiate from the interior

of the aggregate out into the surrounding paste. The cracks are empty (not gel-filled) when formed. Small or large amounts

of gel may subsequently exude into the cracks. Formation of the alkali silica gel does

not cause expansion of the aggregate by itself. Observation of gel in concrete is

therefore no indication that the aggregate or concrete will crack. Only

moisture can cause the expansion and resultant cracking Alkali silica reaction is diagnosed primarily by four main

features

|

From this brief overview of the literature on the mechanisms, the

following

summarizes present knowledge on ASR:

- ASR is a reaction between the OH in the pore solution with amorphous

or poorly

crystallized silica in the aggregates.

- The reaction product imbibes water and expands.

- The presence of water or RH higher than 80’% is necessary for the

gel formed to

expand and induce concrete cracking.

- Some siliceous mineral admixtures deplete the alkalis horn the pore

solution, lowering

the pH, therefore decreasing the likelihood of ASR.

- The aggregate type and size distribution play a significant role in

the expansion

measured in concretes

- Other factors influencing the cracking due to ASR include air

entrainment and possibly

WlC.

|

|

ASR-induced cracking can be confused with other forms of

cracking. As a result, inspectors sometimes misdiagnose the problem and then

apply rehabilitation techniques that may actually make the ASR problem

worse. Inspectors and engineers therefore need better, more accurate tools

for identifying ASR in existing concrete structures and for deciding on the

best treatment for existing and current structures. Several such tools were

developed under the Strategic Highway Research Program (SHRP): • Handbook for the Identification of Alkali-Silica

Reactivity in Highway Structures, an easy-to-use field guide for

distinguishing ASR-related cracking in various types of concrete roads and

structures.

• A fast and simple test for detecting the presence of

ASR in concrete.

• A fast and reliable means of determining an

aggregate’s potential reactivity to alkalis.

• Eliminating or Minimizing Alkali-Silica

Reactivity, a report that identifies available options for alleviating

ASR damage in concrete pavement and structures. |

| ASR expansion can be reduced to acceptable levels by use of Type F fly

ash and by use of lithium nitrate additive in accordance with the

manufacturer’s recommendations. |

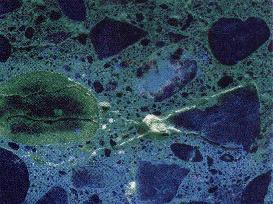

| The only indisputable evidence that ASR has developed in concrete is

the presence of ASR gel reaction products. In the early stages of

reactivity, or under conditions where only small quantities are produced,

ASR gel is virtually undetectable by the unaided eye, and revealed only with

difficulty by a skillful observer using a microscope. Thus, ASR may go

unrecognized in field structures for some period of time, possibly years,

before associated severe distress develops to force its recognition and

structure rehabilitation. Use of uranyl (uranium) acetate fluorescence

method has been developed. This method can be used to monitor possible ASR

prior to development of serious distress and to confirm ASR existence. ASR

is uniquely characterized by production of a gel-like reaction product. It

is composed of essentially of silica, the alkalis (sodium and potassium),

and calcium in the presence of water. Uptake of water by the gel is the

primary factor determining volume changes associated with ASR. The gel may

be present in large or minute amounts in aggregates, aggregate sockets, air

voids, fractures, and on the surfaces of externally formed concretes. By

application of uranyl acetate solution to a surface containing the gel, the

uranyl ion substitutes for alkali in the gel, thereby imparting a

characteristic yellowish-green glow when viewed in the dark using short

wavelength (254 nanometer) ultraviolet light. ASR gel fluoresces much more

brightly than the cement paste due to the greater concentration of alkali

and, therefore, the uranyl ion in the gel.

The presence of ASR gel will be revealed in UV light by a yellowish-green

fluorescent glow. Deposits will be localized in cracks, air voids, certain

aggregate particles and, in severe cases, as broad films in aggregate

particles and fractured surfaces. Such films on sawed and cored surfaces may

reflect as "smear" from sawing or cutting. Fractured surfaces eliminate this

effect and most clearly reveal undisturbed ASR gel deposits.

|

| Damage due to alkali-silica reaction (ASR) in concrete is a phenomenon

that was first recognized in the U.S. since 1940 and has since been observed

in many countries. Despite numerous studies published, the mechanism is not

yet clearly understood. Nevertheless, the three major factors in concrete

have been identified, i.e., the alkalies contained in the pore solution,

reactive amorphous or poorly crystallized silica present in certain

aggregates, and water. It was found that air content is the most important

variable (other than the three majors factors cited above) that increase

expansion of concretes affected by ASR. |

2.1. ASR Mechanisms

Most researchers agree that the main reaction of ASR is the reaction between

certain forms of silica present in the aggregates and the hydroxide ions (

OH) in the pore

water of a concrete. Very early in the hydration of cement calcium

ions are

incorporated in the hydration products but potassium and sodium stay in

solution and

eventually they are partially incorporated into calcium silicate hydrate

(C-S-H) and

monosulfate (AFJ). Hydroxide ions from the hydration of portland cement

result in a pore

solution having a pH of at least 12.5. Soluble alkalies raise the pH to

about 13 or

higher. Also, the amount of alkalis present in the pore water is related to

the amount of

soluble alkalis present in the cement. If the

silica is well crystallized the vulnerable sites are only at the exterior

surface of the

aggregate (Figure 1a), but in the case of poorly crystallized silica, there

are many

vulnerable sites in the aggregate structure, leading to disintegration of

the silicate network. To keep a neutral charge balance, the cations Na+ and

K+ diffuse

toward the hydroxide ions to react with them and the resulting product is a

gel-like material. The migration of cations of

Na+ and K+ is

slow, therefore the migration of Ca2+ takes place. If the gel is high in

calcium then the gel

is not expansive when exposed to water and, therefore, may not induce

cracking in

concrete. This theory rests on the assumption that calcium could be

available. Diamond

found that there is very little calcium in the pore solution.

This is expected since

the high pH causes the volubility of Ca(OH)2 to be depressed. Nevertheless,

calcium could

be dissolved from the solid phase of cement paste to produce a gel. Most

researchers do

not mention the distinction between “safe” and “swelling” gel but there are

acknowledgments that there are more than one composition of gel produced by

ASR.

The formation of the gel per se is not deleterious. The deterioration of the

concrete structure is due to the water absorption by the gel and its

expansion. The RH must be higher than 80% for the gel to swell although it can be

formed at

lower relative humidity. According to Hobbs the progression of the

swelling of ASR

gel follows the general patterns. As the tensile strength

of the system is

exceeded, cracks will form and propagate. As there is not a preferential

direction for

cracks to propagate and also the sites of crack initiation are randomly

distributed in the

specimen, map cracking will be characteristic of ASR deterioratio. The sites of

the cracks are determined by the location of the reacting silica on the

aggregates and the

availability of OH in the vicinity. |

| Aggregates exhibiting this type of reactivity contain various forms of

reactive silica. For convenience, CSA Standard A23.1-Appendix B, divides

alkali-silica reaction into two categories according to the type of reactive

silica involved.

1. Alkali-silica reaction that occurs with poorly crystalline or

metastable silica minerals and volcanic or artificial glasses: Aggregates

containing such materials (see

Table 5-7 and CSA A23.1-Appendix B) may cause deterioration of concrete

when the reactive component is present in amounts as small as 1%. Cracking

of concrete containing these aggregates and a high alkali content is usually

seen within 10 years of construction.

2. Alkali-silica reaction that occurs with various varieties of quartz such

as chalcedony, cryptocrystalline, and macrogranular quartz: Aggregates

containing such forms of quartz may cause deterioration of the concrete when

the reactive component is present in amounts as small as 5% by mass of the

aggregate and there is a high alkali content. Cracking of the concrete may

be seen within 10 years of construction. Canadian experience has been that

this category also includes several slowly expanding aggregates in which

micro-crystalline quartz is thought to be the reactive component. Rocks such

as greywacke, argillite, quartz-wacke, quartzite, hornfels, granite and

granite gneiss are some. See

Table 5-7 and CSA A23.1-Appendix B for a more complete list. Such rock

types may not show cracking and deterioration for up to 20 years. In other

cases however, particularly when exposed to deicing salts, cracking may

occur in 5 years or less.

Visual Symptoms of Expansive ASR. Typical indicators of ASR might be any

of the following: a network of cracks ( Fig.5-20);

closed or spalled joints; relative displacements of different parts of a

structure; or fragments breaking out of the surface of the concrete

(popouts) ( Fig.

5-21). Because ASR deterioration is slow, the risk of catastrophic

failure is low. However, ASR can cause serviceability problems and can

exacerbate other deterioration mechanisms such as those that occur in frost,

deicer, or sulphate exposures.

Mechanism of ASR. The alkali-silica reaction forms a gel that swells as it

draws water from the surrounding cement paste. Reaction products from ASR

have a great affinity for moisture. In absorbing water, these gels can

induce pressure, expansion, and cracking of the aggregate and surrounding

paste. The reaction can be visualized as a two-step process:

1. Alkali hydroxide + reactive silica gel -> reaction product (alkali-silica

gel)

2. Gel reaction product + moisture -> expansion

The amount of gel formed in the concrete depends on the amount and type of

silica and alkali hydroxide concentration. The presence of gel does not

always coincide with distress, and thus, gel presence does not necessarily

indicate destructive ASR.

Factors Affecting ASR. For alkali-silica reaction to occur, the following

three conditions must be present:

1. reactive forms of silica in the aggregate,

2. high-alkali (pH) pore solution, and

3. sufficient moisture.

If one of these conditions is absent, ASR cannot occur. |

| Examples of reactive aggregates are chalcedony, porous flint and some

types of sandstone. The reaction leads to the formation of a gel that has a

tendency to absorb increasing amounts of water, which causes swelling. The

swelling forces the concrete to expand, resulting in gel surfacing and loss

of concrete integrity. |